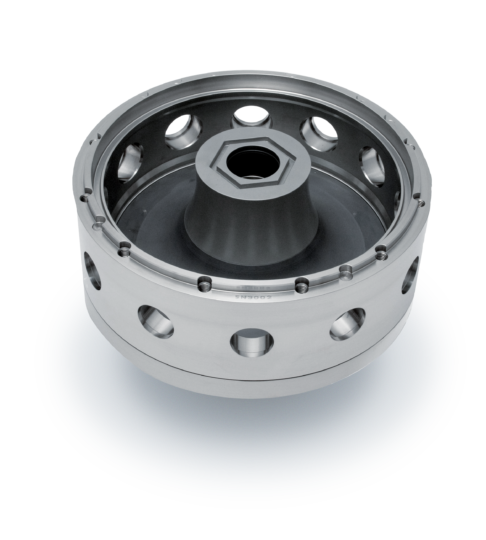

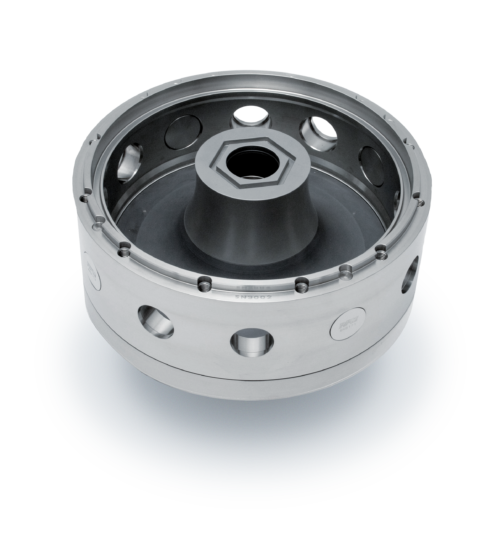

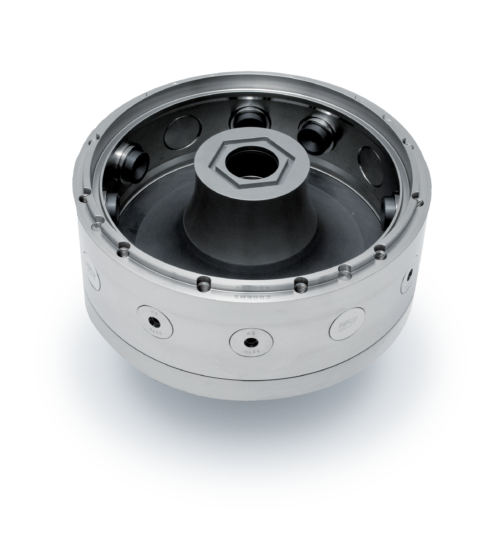

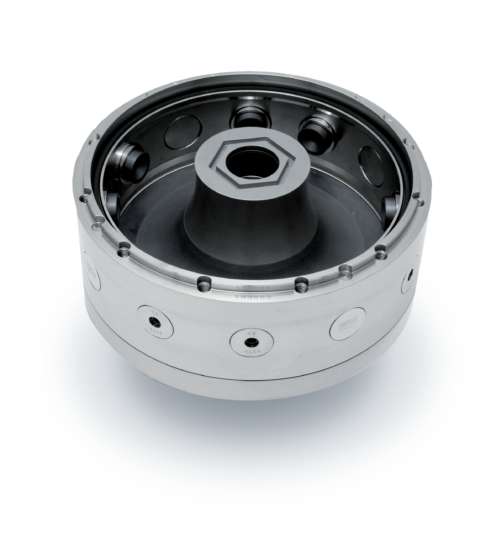

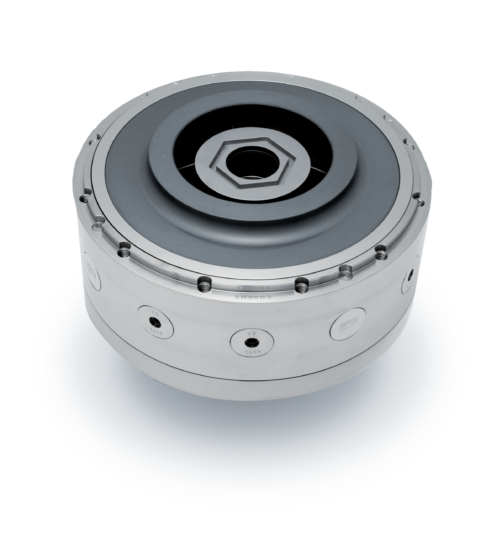

Long Life. Less Maintenance.

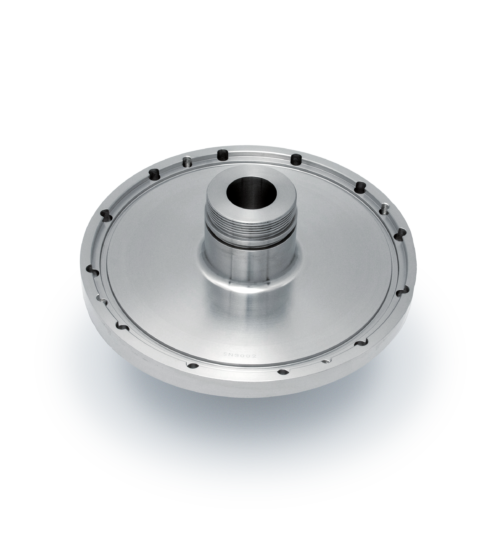

This atomizer wheel was redesigned to include the following features.

Drive Plate - Titanium

This component is manufactured from aircraft grade titanium.

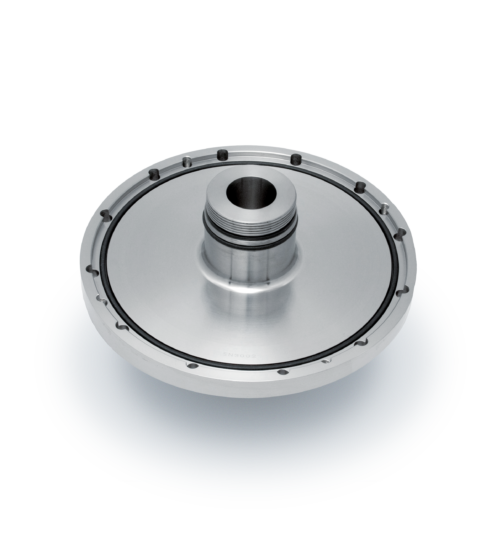

O-Rings

The three o-rings on the drive plate plus an o-ring between the ceramic lower wear ring and the case are added to the drive plate to allow for the ceramic lower wear ring to float during operation.

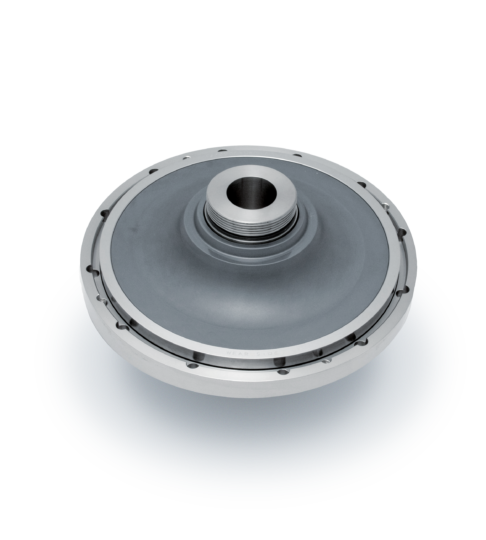

Ceramic Lower Wear Ring-Titanium

This wheel design allows for a one piece ceramic lower wear ring that is contained with a titanium ring with an engineered interference fit. The titanium containment ring keeps the ceramic wear insert under compression during operation. Titanium material is used to prevent the chance of stress corrosion cracking. The design incorporates a stepped area with an o-ring seal between the ceramic lower wear ring and cone nut. This design prevents the slurry from reaching the stem of the drive plate and migrating underneath the ceramic lower wear ring.

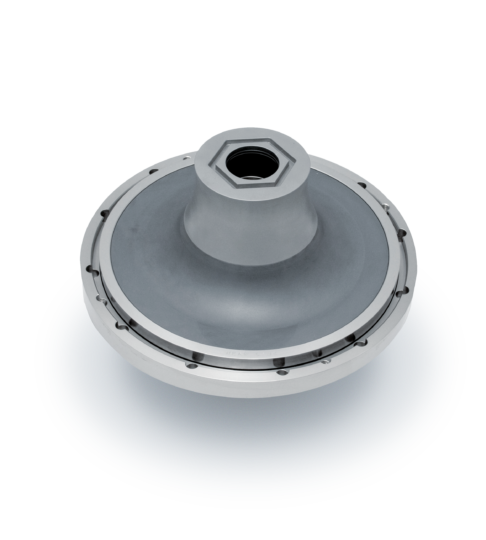

Cone Nut - Modified Long

The ”Long” cone nut design offers many advantages over the standard cone nut design. The four slots on the top of the standard cone nut have been replaced with a hex that is not exposed to the outside diameter of the cone nut. The cone nut covers the entire atomizer spindle, greatly reducing the amount of wear that occurs on the cone nut. Customers have experienced a substantial wear life increase with the design changes made to this cone nut.

Case-Titanium

This component is manufactured from aircraft grade titanium. The case is symmetrical for easy one hundred and eighty degree rotation of the nozzles and allows for even wear on the outside diameter of the case.

Nozzle Plugs-Titanium

The nozzle plugs are made from aircraft grade titanium.

Nozzle-Titanium

This nozzle incorporates a hardened upper cup for increased wear resistance. The hardened upper cup reduces wear on the nozzle, protecting the case from structural damage and ensuring that the wheel remains in balance. With this design, the nozzle is able to be removed and rotated for longer wear life of the component.

O-Ring

The o-ring on the case allows for the upper wear ring to float during operation.

Upper Wear Ring-Ceramic-Modified-Titanium

In other designs, the lid acts as a structural component as well as a wear component. The wheel is designed to allow for RPM’s patented upper wear ring design. This design separates the lid as a structural component and the upper wear ring as a wear component. The upper wear ring wear insert can be offered as a heat treated stainless steel or ceramic for extreme wear applications. The wear insert is contained with a titanium ring for superior corrosion resistance.

For more details, see our Upper Wear Ring-Ceramic-Modified-Titanium page.

Lid-Titanium

This component is manufactured from aircraft grade titanium. This patented design allows for the lid to be a structural member only and the upper wear ring becomes the main wear component.

Fasteners

The fasteners are made from aircraft grade titanium.