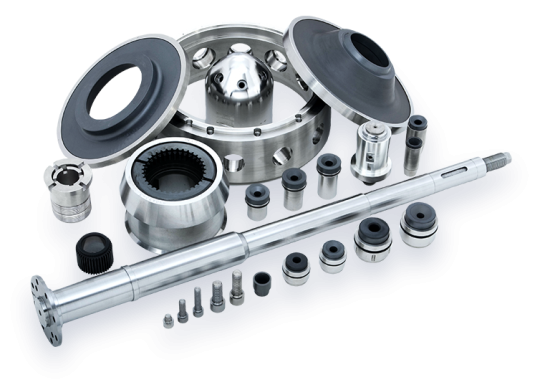

RPM Solutions manufactures new and rebuilds used rotary and stationary atomizer components for spray dryer applications and flue gas desulfurization units used in coal fired power plants, waste-to-energy centers, and incinerating facilities. The company stocks approximately two hundred different components for these systems. Learn More

Atomizer Nozzle Design – RPM Solutions’ three-piece nozzle design offers superior wear life over other nozzle designs for flue gas desulfurization systems and other spray dryer applications.

Cone Nut Design Changes – RPM Solutions has implemented design improvements to increase the wear life and eliminate wear on the spindle.

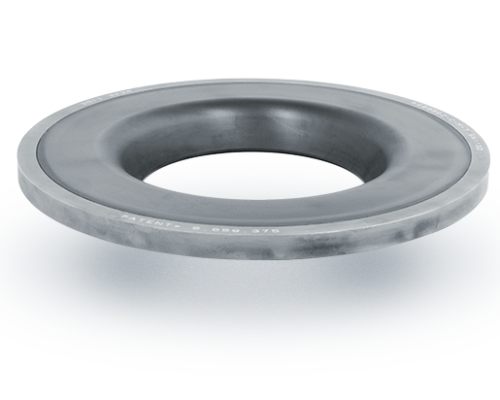

Upper Wear Ring-Ceramic-Modified-Titanium – RPM Solutions’ ceramic wear ring greatly increases the wear life over traditional metallic wear rings.

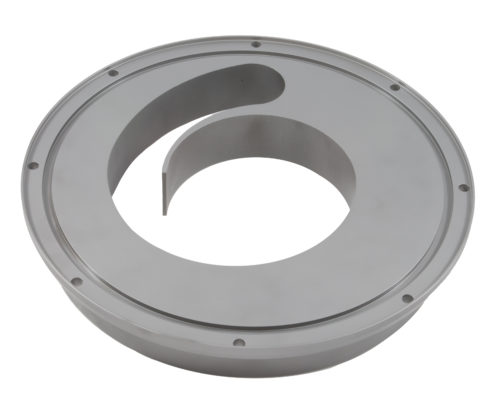

Center Distribution Plate-Intermediate – RPM Solutions Center Distribution Plate-Intermediate resolved vibration issues experienced at a plant utilizing the standard short version of this component.

Reverse Taper Nozzles – RPM Solutions has developed a patent pending new nozzle geometry that optimizes the spray pattern of the atomized slurry.

RPM Solutions rebuilds existing systems to dependable operating condition for spray dryer applications and flue gas desulfurization systems. Learn More

The Atomizer Monitoring System is a comprehensive set to tools designed to allow a power plant to effectively manage all aspects of maintaining an atomizer system for flue gas desulfurization systems and other spray dryer applications. It includes Inventory Management, Standardized Procedures, and Real-time Monitoring and Data Collection.

Keep track of all of the parts in your inventory. Monitor run-time hours and maintenance history on each part. Make intelligent, informed decisions as to when to perform maintenance and retire parts. Measure return on investment.

Packages available to meet a variety of different maintenance and monitoring needs. Learn More

Use the Atomizer Maintenance Program to take the headaches out of maintaining your Flue Gas Desulfurization System or other spray dryer applications. Learn More

RPM Solutions manufactures new and rebuilds planetary atomizer gearboxes used in flue gas desulfurization systems and for other applications. RPM currently rebuilds and stocks parts for 2.65, 2.95, 3.21, and 3.672 planetary gearbox ratios. Learn More

RPM Solutions repairs atomizer shafts by laser welding the worn surfaces and grinding those surfaces back to the proper tolerances. Laser Repair Technology (LRT) is a process owned and operated by our sister company RPM Innovations. Learn More

RPM Solutions offer many engineering services. Learn More